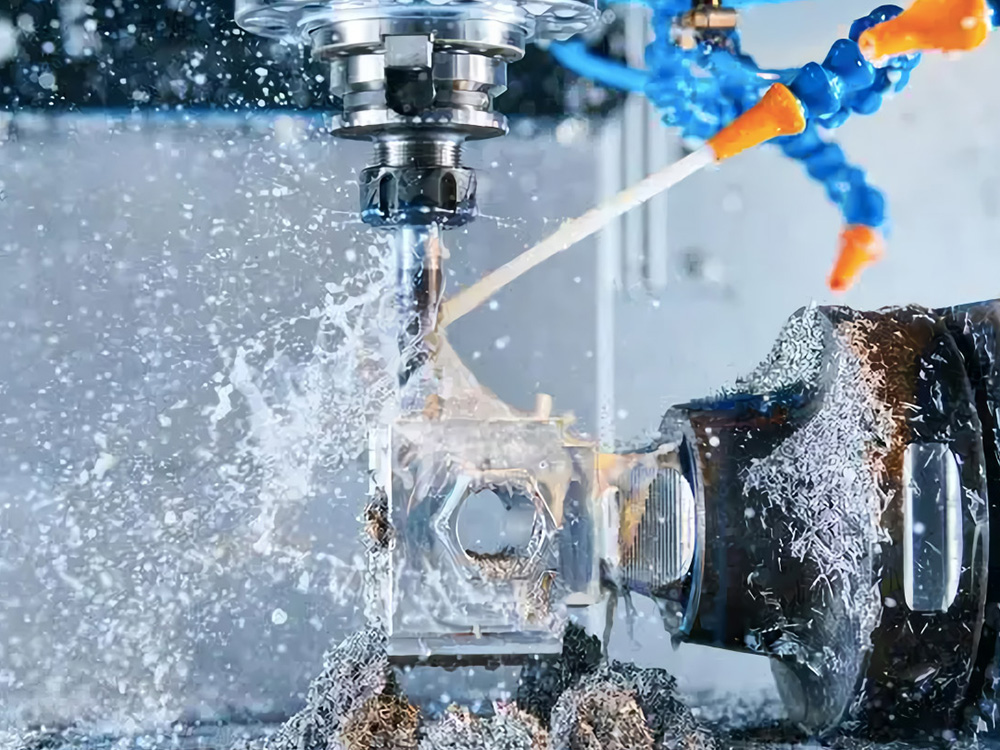

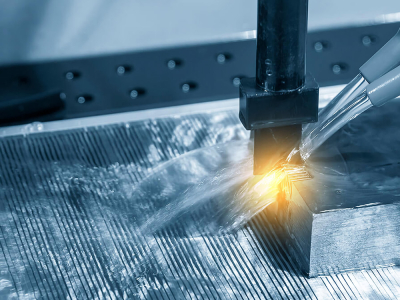

Fully synthetic cutting fluids

Product Features:

1.Durable and stable performance - excellent filtration and resistance to hard water, so Magic Power Z-16 remains clean and transparent after long-term use; very long service life, in a centralized fluid supply system can be guaranteed for a minimum of 3 years without replacement, with very low carryover, effectively reducing processing costs.

2.Excellent anti-corrosion performance - contains highly effective rust inhibitor and metal corrosion inhibitor, has excellent anti-corrosion effect on ferrous metals.

3.Excellent anti-foam performance - Special strong anti-foam ability, so that it can adapt to high system pressure for a long time without adding defoamer.

4.Environmentally friendly - Reduces costs by reducing the amount of added concentrate. The waste liquid does not contain substances harmful to the environment and does not lead to environmental degradation after cleaning and disposal.

Product Description:

Magic Power Z-16 Full Synthetic Cutting Fluid is a chemical synthetic fluid manufactured with the latest technology using the most advanced surface treatment technology, making this product has good iron chip settling and rust prevention ability, and very low ability to control foam, special additives significantly increase the processing accuracy and service life of the grinding wheel.

Product Features:

Excellent anti-corrosion performance - does not contain phenol and nitrite, does not contain diethanolamine, has excellent anti-corrosion performance, especially suitable for the roll grinding process to ensure that the surface of the grinding process after a long period of storage is not subject to corrosion.

Excellent filtration - using the latest technology and chemical surface treatment method, due to which it has good oil resistance and exceptional chip settling ability; to prevent abrasive chips from flowing through the fluid supply system back into the processing area, to ensure the accuracy of the grinding surface.

Test items |

control parameter |

Test items |

control parameter |

external condition |

Clear yellow liquid |

Flash point (COC) |

not applicable |

smells |

faint odor |

Conductivity/ms |

<3 |

Density (H2O=1) Refractive index |

0.98~1.11 3.0±0.2 |

pH (undiluted stock solution) pH (5% dilution 25°C) |

not applicable 9.7±0.3 |

Mixing Instructions:

*Recommended amount: 5 to 10% for low grinding requirements and high surface finish.

*Recommended usage levels: 5 to 10% for low grinding and surface finish requirements; 10 to 15% for high demands on grinding and surface finish.

*Typical operating usage: 5% (1:19) to 15% (1:6).

*If usage exceeds typical levels, please contact us for technical support.

*Mix with water (dilute concentrate with water).

*Whenever possible, dilute with deionized water to extend fluid life, reduce the amount of concentrate used, and maximize fluid performance.

*Do not add any other substances to the concentrate or dilution unless authorized by Magic Power Technical Service.

*Concentration control can be obtained by using a refractometer and refractive index to obtain the percentage concentration of a dilute solution: refractometer reading x refractive index = percentage concentration.

Before testing a sample, calibrate the refractometer with deionized water to a reading of 0.0.

Before testing a sample, calibrate the refractometer with deionized water to a reading of 0.0.

Select a cleaner (uncontaminated) process fluid for sampling.

Recommendations for use:

*Most suitable for use in poor working conditions or workshops where extreme cleanliness is required.

*At the beginning of use, the product has a very slight odor, which disappears after a day or two.

*Please clean the machine and treatment fluid tank/basin before using this product, and then add the prepared Magic Power treatment fluid.

*Strictly control the concentration (regular replenishment of new liquid), generally add about 5%, 7% of the added amount is more favorable to prolong the service life of the entire treatment liquid reservoir.

*If there is floating oil in the process fluid reservoir/reservoir, it should be removed regularly to prevent bacterial growth.

*Do not add/mix other products without permission, contact Magic Power for technical support if necessary.

Storage instructions:

*Avoid direct exposure to sunlight;

*Avoid contact with fire and heat sources; avoid mixing with moisture;

*avoid contact with strong oxidizing agents, strong bases and strong acids;

*After opening the lid and removing part of the concentrate, it should be tightly closed to prevent contamination of the product in the drum;

*For storage, place in a ventilated and cool place;

*The darkening of the appearance of some products after long-term storage does not affect their use.

*If the product freezes at low temperature, please place the product in a 20℃ environment to thaw completely, and then it can be used without affecting the effect.

Attention:

Avoid contact with eyes and ingestion of Magic Power Z-16 concentrate. In case of contact, immediately rinse eyes with clean cold water or seek medical attention.

Other aspects:

Due to minor formula adjustments or normal manufacturing changes, final product data may vary slightly from those shown in the table. This is normal and will not be reported without prior notice!