Lubricants for Steel Cutting

1.High lubricating properties

2. Effective cooling properties

3. Good cleaning and sedimentation

4. Excellent anti-corrosion properties

5. High flash point and low volatility

6. Good antioxidant properties

Production Description:

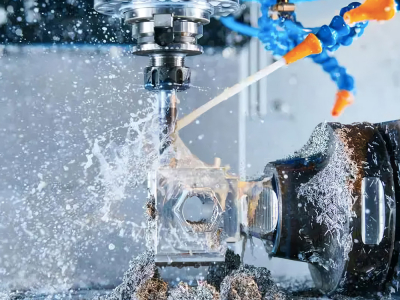

Carbides (such as tungsten - cobalt and tungsten - titanium - cobalt) are prone to combustion problems and cracks during grinding due to their high hardness and wear resistance. By optimizing lubrication and cooling properties, Lubricants for Steel Cutting can significantly improve the quality and efficiency of processing.

Advantages and features:

1.High lubricating properties

Rigid alloy grinding oil is composed of high-performance high-deformation additives, which can form a stable lubricating film during the grinding process, effectively limit the coefficient of friction, reduce friction and wear between the grinding wheel and the workpieces, lengthen the presence of the grinding wheel carrier, and improve machining accuracy.

2. Effective cooling properties

The high temperature that occurs throughout the grinding process can easily lead to workpiece burns and grinding wheel wear. Carbide grinding oils have significant thermal conductivity and can quickly eliminate heat in the grinding area, maintain the low-temperature condition of parts and grinding wheels, and prevent heat damage.

3. Good cleaning and sedimentation

Metal and abrasive particles generated during the grinding process affect the quality of the machining and the service life of the grinding wheel. Carbide grinding oil can make the grinding area smooth quickly, separate particles from abrasive particles, keep the abrasive fluid clean, and avoid secondary wear.

4. Excellent anti-corrosion properties

Abrasive oil contains anti-corrosion components that can form a protective film on the floor of the product, prevent rust during storage and transportation, and ensure the quality of processing.

Application Scenario:

1. Manufacture of carbide cutting tools

In the manufacturing process of cutting equipment from difficult-to-machine alloys (e.g., turning knives, milling cutters, chisels, etc.), high-precision grinding is required. Carbide grinding oils provide excellent lubricating and cooling properties, ensuring dimensional accuracy of retarding tools and floor quality.

2. Mold Making

In mold processing (such as stamping, casting, etc.), carbide grinding oil can successfully reduce the wear of the grinding wheel, improve the mold processing accuracy and media life, and limit production costs.

3. Aerospace Component Processing

Aerospace companies have very strict requirements for the accuracy of parts and the comfort of the floor. Cemented carbide grinding oil can meet the needs of high-precision grinding, ensure the processing accuracy of parts, meet the stringent requirements of the aerospace industry.

4. Automotive Parts Manufacturing

In the production of key components such as automotive engines and transmissions, sophisticated alloy grinding oils can improve machining efficiency, reduce grinding wheel consumption, reduce production costs, ensuring component wear resistance and supplier presence.