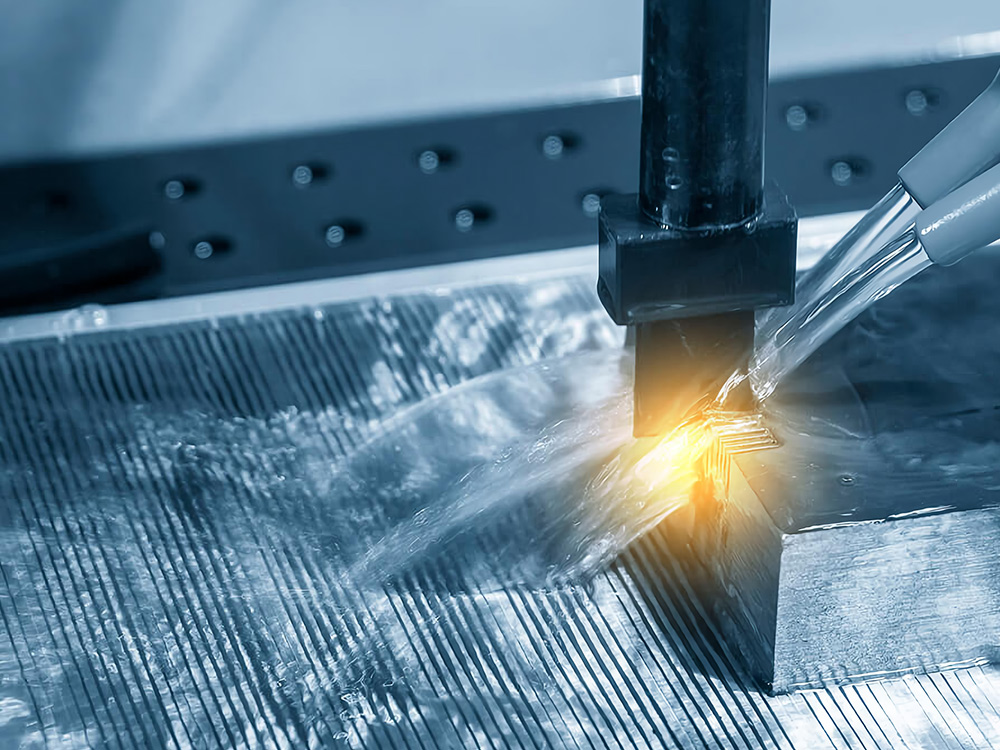

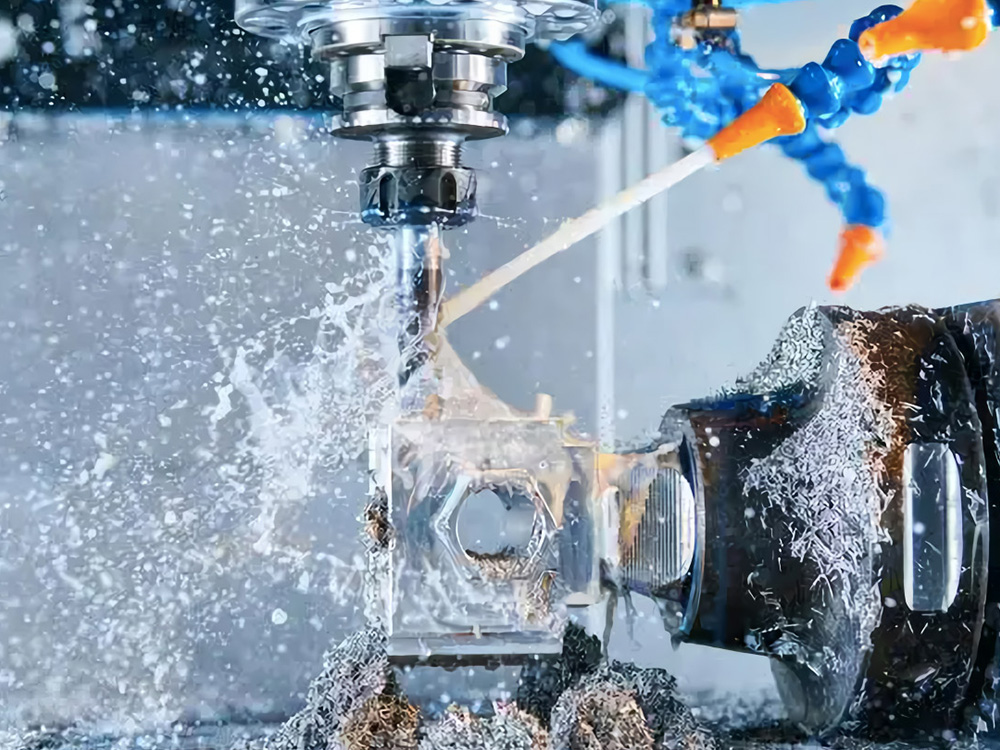

emulsified oil cutting fluid

1.Excellent anti-corrosion properties, good protection for ferrous metals.

2.Good resistance to hard water, not easy to form oil and soap.

3.Very low odor, always maintain a fresh working atmosphere.

4. Does not contain nitrites, benzene, phenols and other harmful substances.

5. A solution with 5% purified water is close in color to water.

Product Description:

Microemulsified extreme pressure cutting fluid is a microemulsion, brownish yellow in color, made from emulsifiers, surfactants, bioinhibitors, rust inhibitors and other raw materials, fine compounding, mainly designed for ferrous metal processing, to meet most steel processing technologies materials.

Product scope:

Suitable materials: 45# steel, cast iron, some stainless steel and other ferrous metals.

Processing methods: turning, milling, drilling, threading, sawing.

Equipment used: machining centers, CNC lathes, drilling machines, milling machines and others.

Recommendations from the technical department:

1. Regularly check the concentration and pH value of the liquid in the tank, add or change the liquid depending on the situation.

2. If the machine is not used for several days, it is necessary to periodically pump oxygen into the liquid to prevent the growth of bacteria.

3. Remove cutting chips, floating oils and other impurities in a timely manner; it is recommended to equip the machine with sludge and oil removal devices.

4. When mixing products from different brands, conduct compatibility tests in advance.

5. It is recommended to use tap water to ensure optimal operating conditions.

6. Tap water from a well should be used with care to avoid unnecessary wastage.

Directions for use:

Recommended concentration: for processing materials - 1:10~1:20, the concentration should be adjusted depending on the intensity of processing.

When replacing fluid, you must first clean the reservoir, pipes, work tables, fastening devices, processing chips and dirt. Then use the product diluted in a ratio of 1%~2% to pour into the equipment and carry out a full circulation cycle for 20 minutes, then drain the liquid and fill the reservoir with new one.

Storage method:

1. Store in a cool, well-ventilated area, avoid exposure to direct sunlight and rain.

2. Recommended storage temperature: 5°C to 35°C.

3. If, due to improper storage, the product has changed its properties, it is necessary to move it to conditions corresponding to the recommended storage temperature and use it after restoration.

4. Under normal storage conditions, the shelf life is one year.