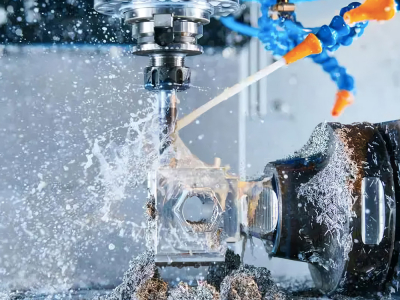

Band Saw Coolant

1.Excellent cooling properties

Effective lubricating and anti-friction effects

3. Excellent cleaning and chip removal ability

4. Stainless and anti-corrosion protection

5. Environmental protection and safety

Production Description:

Band Saw Coolant is a metal processing fluid designed for surface grinding machines, which effectively controls thermal deformation and improves surface quality while providing high-precision grinding. Its main advantages are reflected in cooling, lubrication, anti-corrosion, cleaning and other aspects, suitable for precise flat processing of various materials.

Advantages and features:

1.Excellent cooling properties

During the grinding process, the high-speed friction between the grinding wheel and the workpiece produces a lot of heat. The coolant quickly eliminates heat through the circulation flow, effectively reduces the temperature in the grinding position, and prevents parts from burning, cracking, or deforming due to overheating.

Compared to conventional oil-based refrigerants, the use of more than 30% positive and high-performance refrigerants (e.g., water-based artificial fluids) can improve cooling efficiency.

Effective lubricating and anti-friction effects

Strong deformation additives in the heat transfer fluid form a lubricating film on the grinding interface, reducing the coefficient of friction between the grinding wheel and the workpiece, reducing the grinding force, thereby prolonging the life of the grinding wheel and improving the quality of the part floor.

Experiments have shown that the use of coolant containing highly deformed components can reduce grinding wheel wear by 20 to 40%.

3. Excellent cleaning and chip removal capabilities

The coolant flow can wash away steel and mill particles falling out of the grinding wheel during grinding in a timely manner, prevent clogging of the grinding wheel, and maintain safe grinding efficiency.

Its cleaning effect is especially common at some high-speed grinding points (such as a linear speed of > 50 m/s) and can reduce floor scratches caused by the accumulation of particles on the products.

Application Scenario:

1. High-precision ground grinding

Applied to precision machining of materials with high hardness, such as mold metals and carbides, such as ground grinding of dies and optical dies.

The coolant is designed for low foaming and excessive cleanliness to ensure the floor roughness of the part to Ra0.1μm or lower.

2. Efficient mass production

In the mass processing of automotive factors (e.g., engine cylinders, brake discs) and hydraulic components, the coolant must stabilize cooling, lubrication, and eliminate chips to increase the manufacturing speed.

It is recommended to use a water-based cooling fluid with excess consciousness (5% - 10% concentration) to adapt to the over-floating and over-voltage cooling system.

3. Shredding of Solid Computer Materials

In order to reduce substances such as titanium alloys and high-temperature alloys, the cooler wants to beautify the overall performance of its lubricant under high stress to reduce the adhesion of the grinding wheel and the thermal damage of the product's substrate.

Typical applications include precision grinding of turbine blades and discs in the aerospace industry.

Elements of use and maintenance:

Concentration Control: Daily detection by refractometer, monitoring fluctuations within ±1%.

Filtration System:

Coarse grinding: magnetic separator (50μm filtration accuracy).

Detailed shredding: increasing the filtration of the paper tape (10 μm).

PH maintenance: Maintained at 8.5-9.5 (weekly testing, buffering).